UNIAXLE

an innovation in CNC machining of truck rear axles

Uniaxle

Rear axle machining in a single setup

> to the greatest precision

> in the shortest possible time

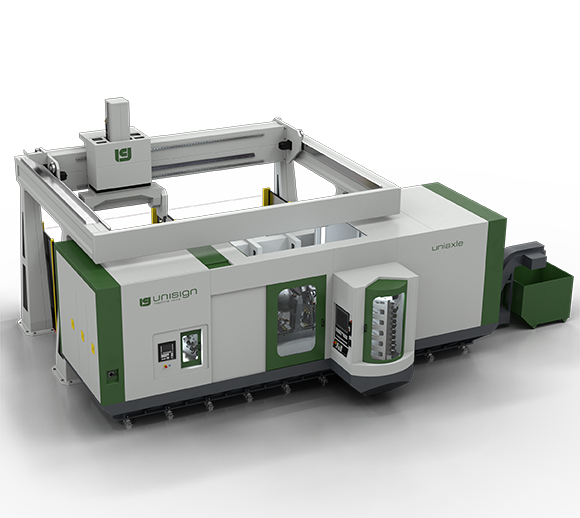

Our UNIAXLE is a revolutionary new CNC machine for machining welded and cast truck rear axles!

You can machine complete truck rear axles in just one set up on ONE single machine. It’s faster, more accurate and saves you money. You won’t need so many different machines, thus saving space on the shop floor. The UNIAXLE CNC machine is universal and can machine a wide variety of rear axles.

Learn more! Download our interesting UNIAXLE webinar

benefits

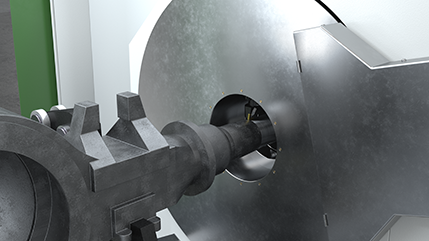

Unique technology – turning head

The UNIAXLE CNC machine is unique: with a cutting tool rotating around the rear axle. The turning head we use is an innovation from our own R&D department. With this innovation we found the ideal balance between accuracy, speed and flexibility.

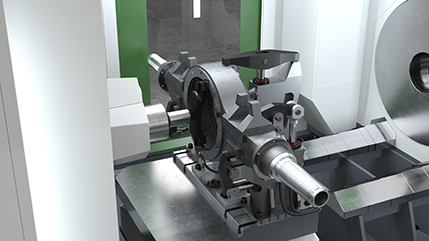

Simultaneous milling and turning

In addition to the unique head, this CNC machine also has a milling spindle. All turning and milling operations on the rear axle are carried out at the same time. Another advantage is the rotation unit which turns the rear axle through 90 degrees so the milling spindle can also machine the rear axle banjo.

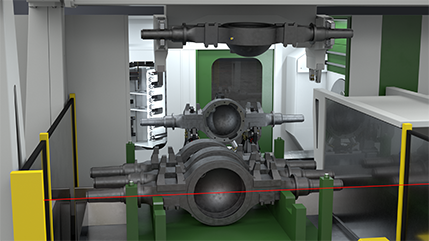

Single clamping

A production line with multiple machines requires many different operations. The frequent lifting, moving and setup operations influence the lead time as well as the accuracy of the machining. Single clamping means greater process reliability and a significant reduction in changeover times!

technical specifications

.

Turning head

- Z-axis750 mm

- Radial axis (x-axis)100 mm

- Spindle power29,3 kW (S1-100%) | 37,5 kW (S6-40%)

- Spindle torque1000 Nm (S1-100%) | 1280 Nm (S6-40%)

- Spindle speed630 min-1

- Tool taperCapto 6

- Number of tool pockets12

- Tool change time9 sec

Milling/drilling spindle

- X-axis700 mm

- Y-axis700 mm

- Z-axis1250 mm

- Spindle power52,4 kW (S1-100%) | 56 kW (S6-40%)

- Spindle torque1000 Nm (S1-100%) | 1375 Nm (S6-40%)

- Spindle speed4000 min-1

- Tool taperCapto 6

- Number of tool pockets24

- Tool change time9 sec

Axis drive and feed system

- Rapid / feed rate X,-Y-,Z-axis40.000 mm/min

Automatic loading

- Unloading/loading in 60 sec

- Overhead loading crane with double gripper

- Input and discharge station

Various

- Fully enclosed working environment

- Vacuum extraction with filter unit

- Measuring probe

- Integrated chip conveyor

- Siemens 840D-sl control

- Touch screen

- Remote access

cnc machine application

- Logistics

We have established a world leading position in front axle machining. Truck manufacturers and suppliers use our UNITWIN CNC machine to produce more than 2 million front axles every year.

For the complex rear axle machining we also have a dedicated solution: our UNIAXLE. With this new CNC machine you can machine cast iron as well as steel welded rear axles to the greatest precision, in the shortest possible time, all in a single setup.

For everything from bogies to wheels and weld preparation to wheel carrier machining, Unisign has highly versatile machines like the Uniport6000 and Uniport7000. These gantry style machining centres are part of the machine tool program that have been designed to deliver extremely high capacity, dynamics, rapid acceleration and offer a generous working area.

applications for logistics