Inspiring customer stories

Unisign Experience@Work

Discover our experience in your industry

Improved steel telescopic covers

New generation of steel telescopic covers

Application: UNICOM6000 machines

Services: Retrofit

CNC machining methods

Learn more about various machining techniques, such as milling, boring, reaming and tapping.

Make an informed decision based on the pros and cons of each technique.

Machine modernisation - retrofit of controls

Machine modernisation boosts your productivity and IT security

Application: Unisign CNC machines with Sinumerik 840D controls

Services: Retrofit

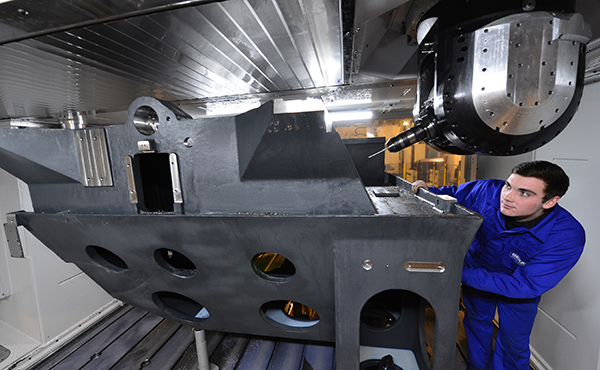

KNDS UK - United Kingdom

Unisign’s friendliness and willingness to help stand out

Application: Machining key components for military bridges and vehicles

Services: Refurbishment

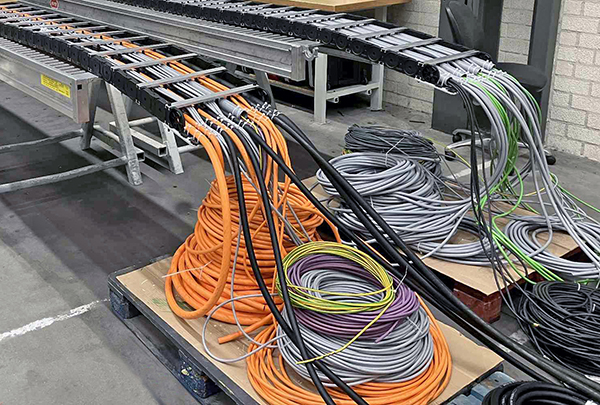

Complete rewiring of CNC machines

Preventive rewiring: avoid wear and tear and increase reliability

Application: all Unisign machines

Services: Advised every 12 years

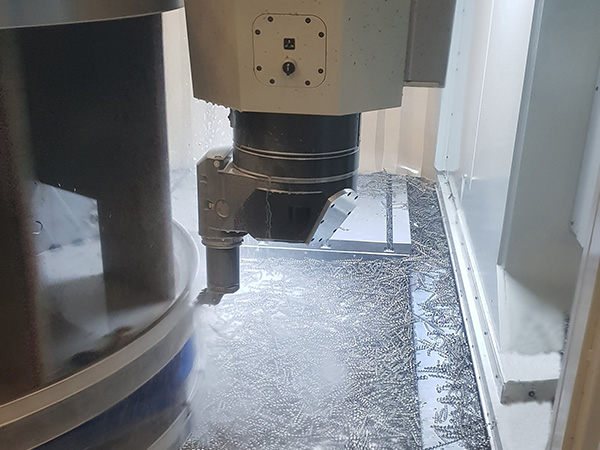

Dry machining versus wet machining

Learn more about the advantages and disadvantages of dry and wet machining.

Make an informed decision based on the specific needs of your machining process.

Clamping techniques

Learn more about the correct use of clamping methods.

Avoid vibrations during operation.

Bharat Forge Kilsta - Sweden

UNITWIN6000: innovative front axle machining

Application: Machining of front axles for trucks and buses

Machine type: UNITWIN6000

Medha Bogies Pvt. Ltd. - India

The perfect fit for bogie machining

Application: Machining of bogie frames for trains

Machine type: UNIPORT6000

Homag Kantentechnik GmbH - Germany

Unisign sets the standard that all other machine manufacturers should live up to

Application: Machining base frames for edge banding machines

Services: Maintenance contract

AMA Anlagen- und Maschinenbau - Germany

Robust, reliable and user-friendly: the UNIPORT6000

Application: Machining of complex cast components and welded constructions

Machine type: UNIPORT7 | UNIPORT4000 | UNIPORT6000

Mogema - The Netherlands

Maintenance and after-sales supported by extensive knowledge

Application: Machining large machining frames

Machine type: UNIPORT7000-OG-KW

BMA Braunschweigische Maschinenbauanstalt AG - Germany

UNIPORT6000 machines for greater machining efficiency

Application: Machining of large components for machines and systems

Machine type: UNIPORT6000 | UNIVERS6 | UNIPORT6

Machining head or main spindle broken?

Machining head rental service and main spindle exchange system

Machine type: All Unisign CNC machines

Services: Minimum downtime in manufacturing

Heinz Baumgartner AG - Switzerland

UNIPORT6000-HV-OG boosts the flexibility and quality

Application: Machining large components

Machine type: UNIPORT6000-HV-OG

Relocation of CNC machines

Completely care-free relocation solutions

Machine type: All Unisign CNC machines

Services: Professional support for relocations

Cleaning tool tapers

Tool taper cleaning: essential for accurate machining

Machine type: All Unisign CNC machine tool taper types

Services: Cleaning systems (standard and customised)

IASA Instandhaltungstechnik AG - Switzerland

Measuring is knowing: Geometry measurements guarantee accuracy

Application: machining industrial components

Services: Geometry checks

Gontermann & Simon - Germany

UNIPORT6000 – indispensable for high-precision machining

Application: 5-axis machining of large, complex components

Machine type: UNIPORT6000

Coek Engineering - Belgium

Retrofitting controls extends lifespan of legacy machines

Application: Machining of pressure vessels and heat exchangers

Machine type: UNIPORT7

De Rooy Slijpcentrum - the Netherlands

Succesful start in CNC milling market using UNIPORT machines

Application: Milling large machine parts

Machine type: UNIPORT4000 | UNIPORT6000

Hofmann Engineering - Australia

State of the art bogie machining on UNIPORT6000

Application: machining of bogie frames for trains

Machine type: UNIPORT6000

Palmse - Estonia

Increased production for PALMS forest trailers

Application: machining vehicle frames for forestry equipment

Machine type: UNIPORT6000

Brück GmbH - Germany

Unisign machines – the first choice for high-precision finishing

Application: finishing of special forged components (e.g. rings and flanges)

Machine type: UNIPORT6000 | UNIPORT7000 | UNIPORT8000 | UNICOM6000

ENGEL Austria GmbH - Austria

Total machining solution with 3 UNICOM6000 machines connected together via an FMS

Application: Complete machining of components for large injection-moulding machines

Machine type: UNICOM + FMS turnkey

STT Servis - Czech Republic

Increasing manufacturing speed with Unisign portal machining centres

Application: Machining large steel plates and weldments for machine parts

Machine type: UNIPORT4000 | UNIPORT6000

HOMAG GmbH, Schopfloch - Germany

Large, made-to-order components up to 12.5 m, processed down to smallest detail

Application: Machining of large parts for through-feed and stationary wood processing machines

Machine type: UNIPORT6000 | UNIPORT7000 | UNIPORT7 | UNIVERS6

Wilo Group - Germany

UNICOM6000 – indispensable for the production of large pumps

Application: Machining of large pump housings

Machine type: UNICOM6000

Rába Axle Ltd. - Hungary

Front axle beams exclusively machined on UNITWIN6000

Application: Machining front axle beams for trucks and agricultural vehicles

Machine type: UNIVERS | UNITWIN

HOMAG Kantentechnik GmbH - Germany

UNIPORT6000: the beating heart of the production process

Application: Machining base frames for edge banding machines

Machine type: UNIPORT6000

GEMAG Gelenauer Maschinenbau - Germany

High accuracy and process stability with Unisign machines

Application: Machining large mechanical components for machine tools

Machine type: UNIPORT6000-HV | UNIPORT7000-KW | UNICOM6000 | UNIPORT8000 | UNIPORT7

VDL Konings - The Netherlands

Performing multiple operations on complex welded structures

Application: Machining complex welded constructions for medical devices

Machine type: UNIPORT6000

Ferdinand Steck Maschinenfabrik AG - Switzerland

Universal machine for small parts and large components

Application: Machining of large and small chassis and undercarriage components for rail vehicles

Machine type: UNIPORT6000

ABB Turbocharging - Switzerland

Old NC programs operate 1:1 on new CNC machine

Application: Machining of industrial components for turbochargers

Machine type: UNICOM7000

Unisign Experience - front axles

Unisign UNITWIN, Machining front axles revolves around efficiency

Application: Truck front axles

Machine type: UNITWIN

Unisign Experience - forklift truck mast profiles

Raising forklift truck mast processing to the next level with Unisign’s UNIMAST

Application: All types of mast profiles

Machine type: UNIMAST

Unisign Experience - pumps

Machine your valve and pump equipment smoothly with Unisign CNC machines

Application: Pump and valve housings

Machine type: UNICOM | UNIPORT