Old NC programs operate 1:1 on new CNC machine

April 14, 2020

We are very proud to share the reference of our highly valued customer ABB Turbocharging, Switzerland:

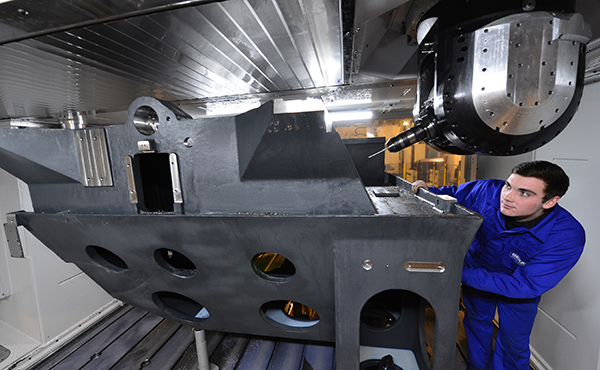

“In 1999 we installed a Unisign Uniturn 6 C system which was still a ‘prototype’ at the time. The system consisted of two machines connected to a conveyor which in those days was considered ‘state of the art’ with 32 pallet spaces. 20 years later, a concept had to be developed to replace the aging machines with an effective system or to undergo a major retrofit. The basic condition was that all ~ 1000 NC programs of the active parts portfolio can continue to be used on a new machine.”

Innovative solution: new UNICOM7000 CNC machine

“Our primary machining processes have been optimized for the component-specific conditions in the past 20 years. The focus in this project was on the robustness of these processes as well as on reliable and fast ramp-up. Due to the very positive experiences of the past years, it was only natural that we considered Unisign in our selection process.

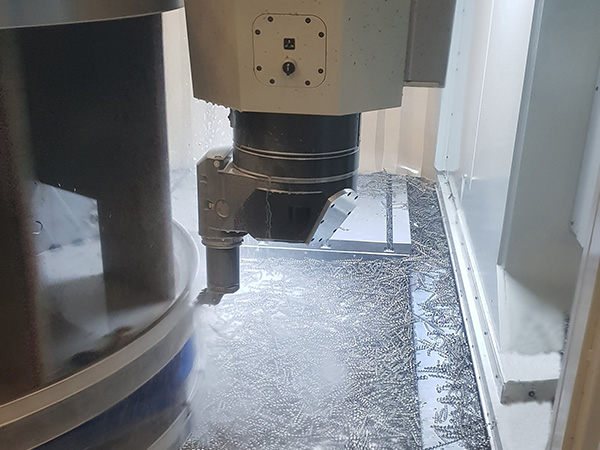

Unisign presented an innovative solution based on a UNICOM7000, with these challenging framework conditions. In combination with a Fastems pallet loading system, the existing portfolio can be managed even more efficient taking into account optimized secondary processes.

Based on this, we preferred purchasing a new machine over a retrofit. The project brought some technical challenges, which makes it all the more important to emphasize that the old NC programs operate 1:1 on the new machine. In a further stage, we’re optimizing the portfolio to make best use and drive efficiency with the opportunities the new machine provides.”

Ready to operate

Andreas Richter concludes: “With the Unisign UNICOM7000, we have an extremely efficient system in connection with the Fastems pallet loading system. It is tailored to our parts portfolio and is ready to operate without a long ramp up period. A successful project in which we have proven that very complex systems can be replaced smoothly with the right partner.”

>> Download the full ABB case study

In focus

Unicom7000

Specification

- X-axis2.675 mm

- Y-axis2.300 mm

- Z-axis1.600 mm