Robust, reliable and user-friendly: the UNIPORT6000

March 11, 2024

AMA Anlagen- und Maschinenbau Amberg GmbH is a contract manufacturing company specialising in CNC machining and steel construction. The company itself operates at two locations. Its principal site in Amberg, Germany focuses on the CNC machining of complex cast components and welded constructions. At its second site in Tachov (Czech Republic), AMA focuses on the manufacturing of complex welded constructions and custom pipelines.

“Our activities cover a number of areas,” explained Andreas Bauriedl (the company’s Managing Director in Amberg). “First of all, there are our conventional mechanical engineering activities, which have always been there. In addition, we supply components for railway vehicles, such as assemblies for trains and carriages. We also carry out work for energy technology companies.”

Portal milling machine

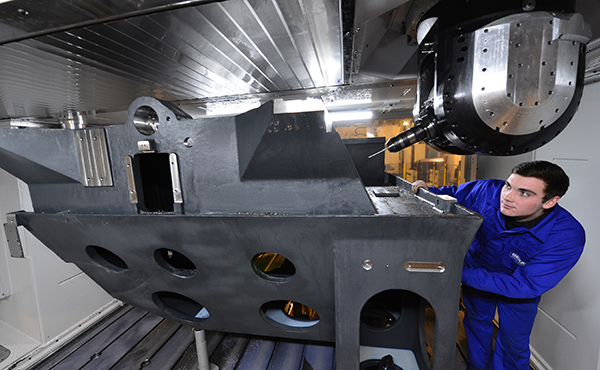

“In Amberg, we can machine large components of up to 40 tonnes and up to 14 metres long,” said Andreas Bauriedl. “Our range of machinery also includes a UNIPORT7 and a UNIPORT4000 from Unisign. In 2022, we asked ourselves what we could do to enhance our range of machinery most effectively. What we wanted most of all was a portal milling machine, as we have now become genuinely enthusiastic about that type of machine. The main reason for that is because using machines of that type means you can approach a workpiece from five sides. Thanks to our positive experiences with Unisign, we decided to buy a UNIPORT6000, which is a robust and user-friendly machine.”

User-friendliness

Andreas Bauriedl: “When purchasing the UNIPORT6000, we didn’t actually have any special requirements in particular. What we had in mind was a standard machine with a machining head comparable to the one on the UNIPORT7. Our UNIPORT6000 is a relatively uncomplicated machine. Our colleagues, who are familiar with operating and programming the UNIPORT7, were also able to use their knowledge and experience on this new machine straight away. That too was one of the reasons for choosing Unisign once again. Several different manufacturers offer portal milling machines, of course, but our longstanding partnership with Unisign was the key reason behind our decision to purchase the UNIPORT6000. Its ease of operation was very important to us. My colleagues enjoy working with the Unisign machines.”

Machining large components

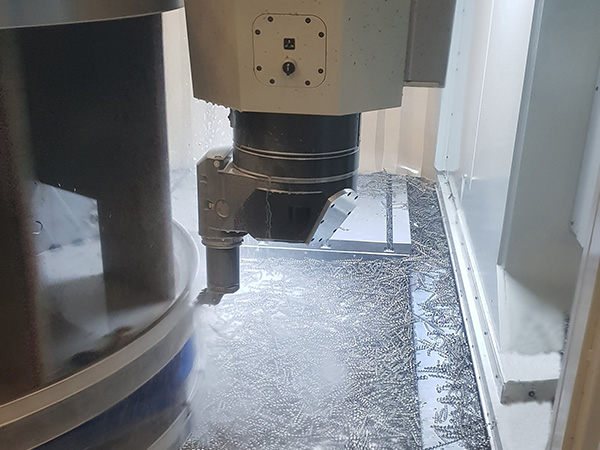

“When manufacturing welded components, the entire workflow is more complex and generally also more time-consuming than when producing cast components,” explained Andreas Bauriedl. “The welded components are produced at our site in the Czech Republic and are then brought to our site in Amberg. The mechanical machining then takes place here.

The Unisign machines play an important role when machining large components of this type. Once machining is complete, additional tasks, such as cleaning, coating and assembly, are then carried out by hand. We ensure the quality of the components by carrying out measurements on our 3D-coordinates measuring machine. We mainly machine components in small runs. In many cases, these are repeat orders for regular customers.”

Assembly and installation

Andreas Bauriedl is also full of praise for the quality and the lead time between submitting the order and the UNIPORT6000 itself being installed: “There’s one thing I must say: the installation of the machine went particularly well and was completed quickly and smoothly. The training provided at Unisign and here at our site was focused and we are also extremely satisfied with it. In fact, not only the installation, but also the entire process leading up to it was faultless and professional. In that regard, it couldn’t have been better. Unisign is a medium-sized company that still deploys personnel who really do take care of everything.”

Rapid integration in component production

Andreas Bauriedl: “In the week immediately after the Unisign training, we were already producing the first components. In the beginning, of course, a few teething troubles still needed to be addressed, but since then, the UNIPORT6000 has been in continual use in our three-shift operation. What we wanted was a user-friendly machine that we could be sure would be working correctly and reliably within a relatively short time, and we’ve got to say: Unisign has delivered.”

In focus

Uniport6000

Specification

- X-axis4.000-24.000+ mm

- Y-axis1.500-5.000 mm

- Z-axis1.000 / 1.250 mm