UNIPORT6000-HV-OG boosts the flexibility and quality

December 12, 2023

In the spotlight: our Swiss customer Heinz Baumgartner AG

In 1962, Heinz Baumgartner started his own business in Tegerfelden, Switzerland using just one small lathe. By day, he repaired agricultural machinery; in the evening, he worked on industrial orders. Under his leadership, the company evolved into what it is today – a contract manufacturing company specialising in machining complex assemblies for sectors including the medical industry. “We have been handling the complete production of robotic arms for one of our customers for more than 30 years now,” the company’s CEO Erwin Baumgartner tells us proudly. “These robotic arms are used in specialist devices for treating cancerous tumours.”

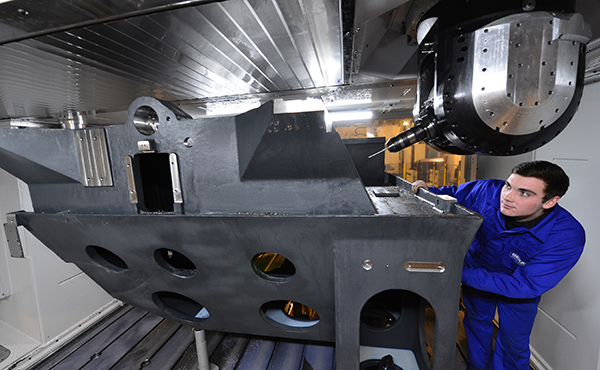

Heinz Baumgartner AG mainly machines large components – as individual pieces and in small batches – for a multitude of highly diverse companies. The company has a state-of-the-art range of machines for this very purpose, which since 2022 has been complemented by a UNIPORT6000-HV-OG.

Trust in Unisign

Erwin Baumgartner is the son of the company’s founder, Heinz. He was introduced to Unisign CNC machines while still in training. Baumgartner: “I was working for a company that used some Unisign machines. While I didn’t work with them myself, I did see first-hand what these machines were capable of every day. I also knew Unsign’s sales representative in Switzerland, HP Müller Werkzeugmaschinen AG, for some time, so when our company had to replace a machine, Unisign quickly came to mind. We purchased the UNIPORT6000-HV-OG in 2021 and it was installed in summer the following year.”

Why the UNIPORT6000-HV-OG?

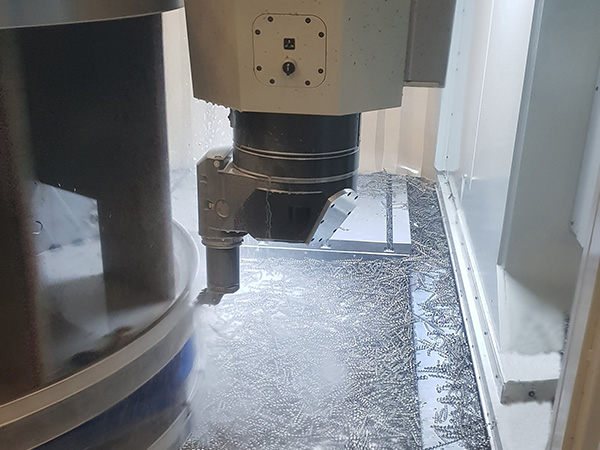

Erwin Baumgartner decided to go for the UNIPORT6000-HV-OG following detailed discussions with his employee, Peter Kuster, who has been working for Heinz Baumgartner AG for 25 years. Baumgartner: “We compared several machines and paid careful attention to the potential that each individual machine had to offer. The 5-axis machining options were a key factor for us. The closed machine design also appealed to us, as it keeps the working environment clean and tidy. Unisign really understood our situation. We were able to convey what we needed or wanted and they put the machine together on that basis.”

A first for everyone

The UNIPORT6000-HV-OG is a top-guided machine: the letters OG in the machine designation stand for ‘obengeführt’, German for top-guided. “This was a first both for us and for Unisign,” says Erwin Baumgartner. “We are the very first company to have a top-guided version of the UNIPORT6000-HV. We are very satisfied with the machine. The UNIPORT6000-HV-OG is the largest machine we have in the three-dimensional range. We use it to machine individual parts and small batches, as well as customised products.”

High flexibility is a must

Erwin Baumgartner explains that, in a contract manufacturing company like his, the flexibility of a CNC machine is very important. Baumgartner: “We never really know what kind of work we will be doing from one month to another. We work on pretty much anything you can think of: from stainless steel plates to welded parts and round components. We have purchased an additional rotary axis to help us manufacture round parts and we also had a positioning system installed in the table so that we can change individual parts more quickly. In essence: we can say that flexibility is extremely important to us.”

UNIPORT and Peter

The person who usually operates the UNIPORT6000-HV-OG at the company is Peter Kuster. The machine was even named ‘Peter’ in his honour. Erwin Baumgartner laughs: “The UNIPORT6000-HV-OG and Peter make one powerful team. Peter was on site every day while Unisign was installing the machine here. That meant he could get to grips with the machine and receive a thorough briefing from Unisign too.”

More possibilities

Erwin Baumgartner has only good things to say about the collaboration with Unisign. Baumgartner: “We got along great with each other. A project that lasts 15 months does come with its challenges, of course. But you just need to find a solution together… and we did. The machine is now running smoothly, exactly how we want it to. With the UNIPORT6000-HV-OG, we now have more machining options to choose from. We can take on a wider variety of orders and deliver products of an even better quality.”

In focus

Uniport6000-HV

Specification

- X-axis4.000 - 24.000 + mm

- Y-axis2.500 - 6.000 mm

- Z-axis1.500 / 1.800 mm