Universal CNC machine for small parts and large components

August 24, 2020

We are very proud to share the case study of our highly valued customer Ferdinand Steck Maschinenfabrik, Switzerland.

Ferdinand Steck Maschinenfabrik AG was founded in 1938. The Swiss family business started out by constructing road rollers and has grown from there. The company’s founder and namesake, Ferdinand Steck, built his first roller at the age of 23. Over the last 30 years, Steck has developed its expertise in building special purpose machines, in particular unique rolling stock units to order. In 2003, Hansruedi Steck handed over the firm to his children, Hans‑Rudolf, Peter and Yvonne Steck, the third-generation to run to company. Some members of the family’s fourth generation are even working in the business already.

Hans‑Rudolf Steck says, “Today we mainly operate in the rail vehicle sector, cog railways in particular. We build specialist and loader wagons, such as workshop wagons, low loader wagons and modular platform

wagons. We also supply components for these rail vehicles, including running axles, running wheels, drive gears, gear racks, brake sets, bogies and more.”

Steck not only manufactures its own products, but also produces under contract. Everything is carried out within the company by a team of 30 specialists: from design to production (mechanical engineering and metalwork) and finishing.

An easy decision

The relationship between Steck and Unisign actually goes back to the 1990s, when Steck bought its very first portal milling machine: a UPB 180. Hans‑Rudolf Steck says, “In 2017, we needed to replace the machine, so we decided to go with a UNIPORT6000. We’ve been highly satisfied with Unisign for all these years, so it was a very easy decision for us.”

Everything on one machine

Hans‑Rudolf Steck continues, “We do things differently; we don’t manufacture parts on a large scale. We often only have one or two units in production at any one time.

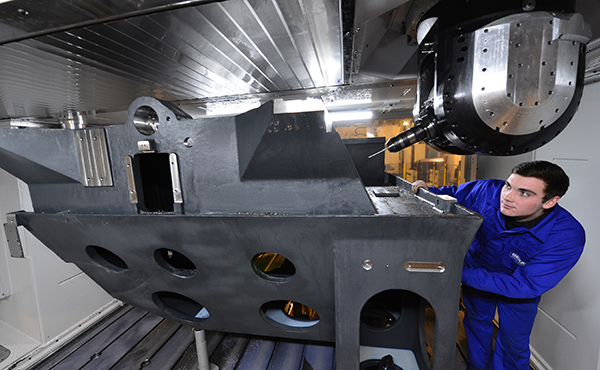

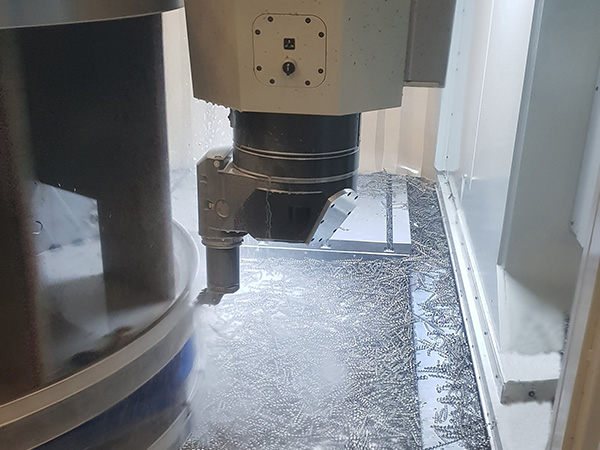

The parts that we machine on the UNIPORT6000 include welded constructions and cubic pieces, as well as long, thin parts such as beams and racks. We work with a wide variety of workpiece dimensions, so we were looking for a universal machine that would offer us maximum flexibility. With the UNIPORT6000, we can manufacture all workpieces quickly, efficiently and with the greatest precision. By using the universal right angular head, which can be swivelled on two planes, we now also have more options at our disposal for more complicated machining.”

Vertical clearance

The UNIPORT6000 is a standard machine in the Unisign range. But the machine’s vertical clearance was modified from 1300 to 1550 mm, specially for Steck. Hans‑Rudolf Steck explains, “That was a major factor that influenced us when purchasing the machine. We process a very high number of cubic parts, and our previous machine was too small for these. Now the UNIPORT6000 comes with this vertical clearance as standard.”

Impressive service from Unisign

Hans‑Rudolf Steck says, “Unisign has long impressed us with its unrivalled products. But something that pleasantly surprised us was the excellent service. If there’s a fault and we get on the phone to Unisign in the morning, an engineer is usually with us by that evening. That’s not something you see every day, and we don’t know any other company that can offer that. Unisign has always surpassed our expectations.”

In focus

Uniport6000

Specification

- X-axis4.000-24.000+ mm

- Y-axis1.500-5.000 mm

- Z-axis1.000 / 1.250 mm