High accuracy and process stability with Unisign machines

November 4, 2020

Customer satisfaction of GEMAG Gelenauer Maschinenbau AG, Germany in a new case study:

GEMAG Gelenauer Maschinenbau AG was founded in 1958 in Gelenau, in former East Germany. In its early days, GEMAG was known more than anything for producing tool turrets for lathes. But after the Berlin Wall came down in 1989, GEMAG saw an opportunity to diversify. Since 2001, the company has specialised in three business segments: assemblies, large-scale mechanics and precision parts manufacturing. “75% of our activities is for customers in the machine tool industry,” says Managing Director Hans-Peter Weise.

“The remaining percentage of our work comes from customers in special vehicle construction, railway engineering, the optics industry and wind turbine production.” In most cases GEMAG relies on contract

manufacturing, but the company also manufactures its own products in the form of mechanical engineering components and assemblies, such as tool magazines for lathes.

“Our staff and apprentices are our most important assets,” says Managing Director Hans-Peter Weise. “They have the expertise to meet the various technical and technological demands that our customers place on them. That’s why we need machinery that offers a high degree of accuracy and flexibility.

“When we sought to expand our business, Unisign and its products played a huge part in that.”

Collaborating since 1998

The oldest Unisign machine used at GEMAG is a UNIPORT7, which dates back to 1998. Hans-Peter explains, “At that time, we acquired another company, and this machine came as part of the deal. Since then, our collaboration with Unisign has only grown stronger.

I remember my staff and colleagues on the management board being extremely pleased with the machine. So, it’s no wonder we came back to Unisign to purchase even more machines. Unisign supplies reliable equipment that delivers great results for years to come. We recently placed an order for a UNIPORT6000-HV, which will be delivered next year.”

High demand for accuracy

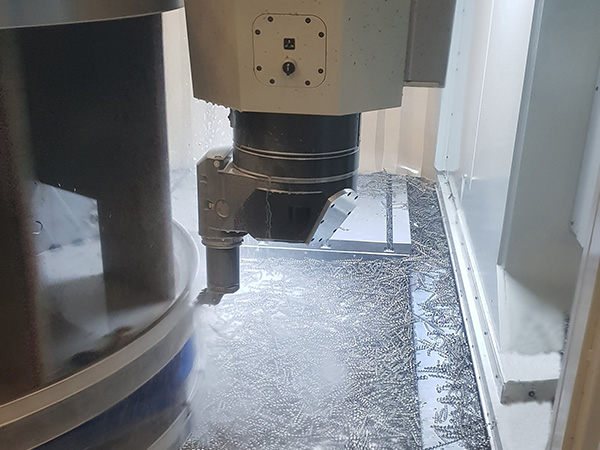

GEMAG predominantly uses Unisign machines to manufacture large components for machine tools. More recently, however, the machines have been increasingly used for machining welded constructions. Hans-Peter continues, “Accuracy and process stability are hugely important for us. We have already produced large components over 1500 mm long on our UNIPORT7000, to an accuracy of 5 µm in terms of straightness and parallelism. The components that we work on call for a very high degree of accuracy. That’s why we use machines from Unisign.”

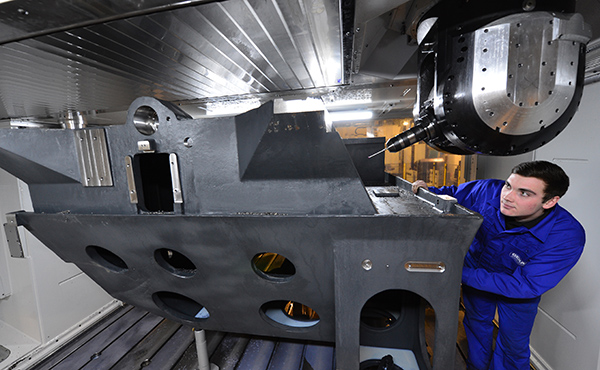

UNIPORT6000-HV

The latest CNC machine that GEMAG has ordered from Unisign needed to be a portal machine, with a horizontal-vertical head. Hans-Peter clarifies why. “We don’t manufacture in bulk; we only ever produce components in small batches. So, we need to have the flexibility to change between tools. A machine equipped with an HV head was an absolute must. And there are very few manufacturers that I know of that can deliver a machine like that.”

Compensation values

Hans-Peter continues, “GEMAG is constantly striving to achieve high efficiency and productivity, and this often requires a balance of machinery, tools and technology. We have always had good experiences with Unisign machines. For example, compensation values are sometimes suggested. The values are entered and then the correction is made. And these corrected values are actually implemented at the spindle. When using other machines, that isn’t always the case.

If our experience with Unisign hadn’t been as good, then we would never have bought five machines from them. Actions speak louder than words!”

In focus

Uniport6000-HV

Specification

- X-axis4.000 - 24.000 + mm

- Y-axis2.500 - 6.000 mm

- Z-axis1.500 / 1.800 mm