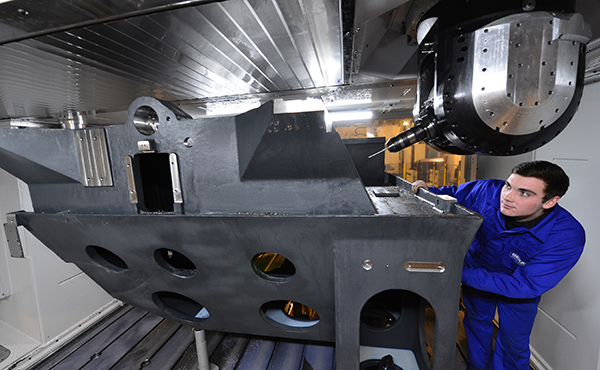

State of the art bogie machining on UNIPORT6000

April 7, 2022

“The time taken to machine a bogie is now 5 hours per bogie, down from 120 hours previous when using older, conventional machines”.

“A few years ago, we won a large contract to manufacture railway bogies for Melbourne’s new trains,” explains David Hubbert, General Manager at the Bendigo site from Hofmann Engineering. “That was a significant turning point for us. It also meant we had to invest in new, high-quality equipment, including a Unisign UNIPORT6000 CNC machine.”

Railway bogies

Hofmann Engineering uses its UNIPORT6000 for machining a wide variety of parts. David Hubbert explains: “We run this machine 160 hours per week and it’s very important for the profitability of the Bendigo site. It’s located centrally in our workshop and forms the heart of our processes. We use it for machining railway bogies for about one full day a week. On the other six days of the week, we use the UNIPORT6000 for a variety of other machining work, such as gear casings.”

Quality and know-how

To execute the contract for 900 railway bogies, Hofmann Engineering wanted a machine that could produce the bogies in the fastest possible time. And preferably, a rigid high-speed machining centre. David Hubbert: “Of course, we could have purchased a cheaper machine, but we made a conscious choice for quality, reliability, accuracy and the best support. Our board travelled to Europe to visit many manufacturers and chose Unisign based on these criteria.”

Best possible support

The board of Hofmann Engineering consists only of people with a technical background. When they went to Europe to inspect various options, they were very enthusiastic about the design of Unisign’s machines and the expertise of Unisign’s people. David Hubbert: “The distance between the Netherlands and Australia is considerable, so you must be able to rely on the best possible support from your machine manufacturer. Our board had full confidence in the Unisign team that would be supporting us. That, too, played a big part when we finally came to making our choice.”

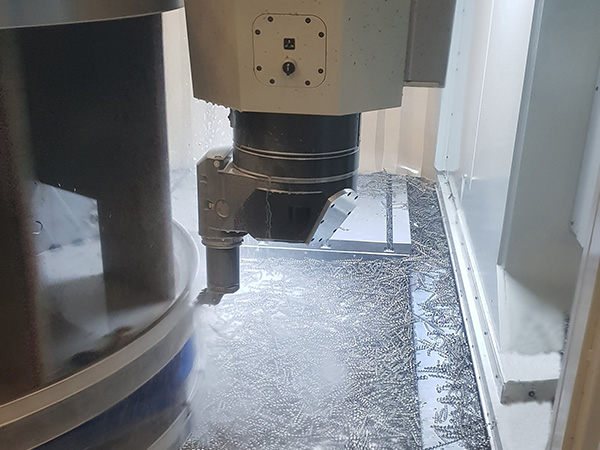

Pendulum machining

One of the key features of the UNIPORT6000 that was crucial for Hofmann Engineering is that the machine is split in the middle. David Hubbert elaborates: “We can be machining one bogie at one end while we position the next bogie at the other. This is really important, because bogies are machined in two set-ups. Besides that, we wanted a turning table at one end because when we produce power station components, we need to achieve high-accuracy turning, milling and drilling. Unisign offered the carousel turning table as a reasonably priced option.”

Taking advantage of new technology

David Hubbert: “Purchasing the UNIPORT6000 was a large technological leap forward for us. Our employees were very excited when we bought the gantry machine from Unisign. The time taken to machine a bogie is now 5 hours per bogie, down from 120 hours previous when using older, conventional machines. The installation was very well organised and conducted by expert technicians. We’ve also been very pleased with the overall (remote) support we’ve received from Unisign. I wouldn’t hesitate to consult Unisign if we ever need an additional machine.”

About Hofmann Engineering

Hofmann Engineering has provided specialist engineering services to Australia’s industry leaders since 1969. The company was founded by two brothers from Germany who started out as toolmakers in their garage. After some time they realised that the quality of gears manufactured in Australia was not great. So they bought second-hand machines, set them up in their newly acquired premises and started making better quality gears. Today, Hofmann Engineering is one of the biggest and most innovative gear-making operations in the southern hemisphere. The company manufactures and services parts for many industries including mining, defence, transport and agriculture. Hofmann Engineering operates from seven cities and employs over 500 Australian workers. In Bendigo, 180 km north of Melbourne, Hofmann Engineering has a 20,000 m2 manufacturing plant.

In focus

Uniport6000

Specification

- X-axis4.000-24.000+ mm

- Y-axis1.500-5.000 mm

- Z-axis1.000 / 1.250 mm