Large, made-to-order components processed down to the smallest detail

April 8, 2021

As part of the HOMAG Group, HOMAG GmbH is one of the world’s leading suppliers of efficient all-in-one solutions for the woodworking industry and trade, and has been in business for more than 60 years. HOMAG machines are popular with small and medium sized companies as well as large companies in the woodworking sector (including IKEA), where they are used to produce furniture and construction components such as doors, windows, stairs and flooring.

“At our site in Schopfloch, Germany, we have around 1,500 employees, who manufacture and develop a broad range of individual machines,” says Willi Maier, the firm’s Head of Large-Part Manufacturing. “We produce huge through-feed machines for mass production, as well as stationary machines for customised production and smaller production runs.”

Ten times Unisign

Unisign first supplied a CNC machining centre to HOMAG back in 1989. And a further nine machines have been delivered since, most recently two UNIPORT6000 machines in 2019. Willi Maier is proud of the long-lasting partnership between the two companies. “The fact that we have ordered so many machines says a lot about our relationship with Unisign. We’ve only ever had good experiences with them, as is clearly shown once again by our latest investment in their machines.”

“From the outset, Unisign offered us the best support we could ever have expected throughout the whole project; not just with the hardware, but also when it came to integrating the software into our environment. We are also extremely satisfied with the level of customer service.”

Welded parts machined to order

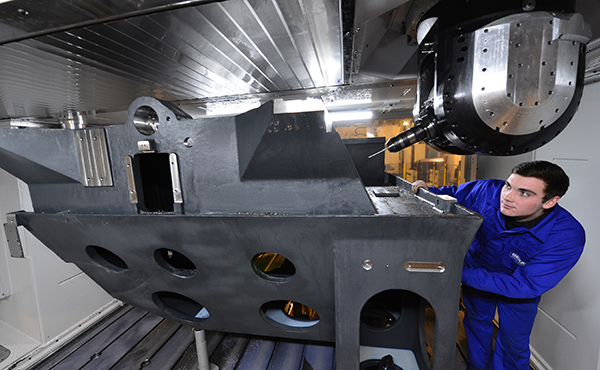

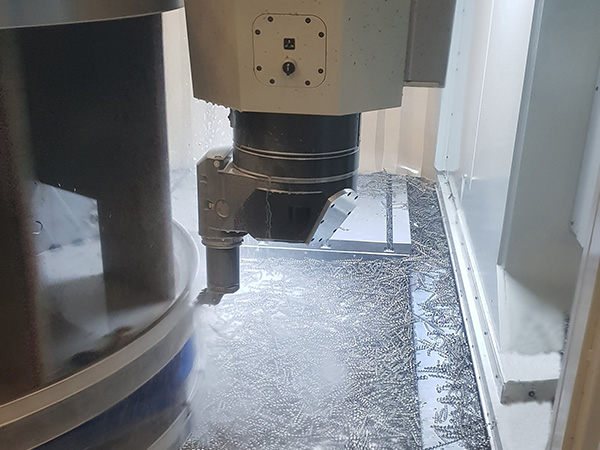

Most of the large parts for HOMAG’s woodworking machines are manufactured on Unisign machines. “These are basic machine components measuring up to 12,500 mm in length,” explains Maier. “And all of them are welded steel parts that are made to order. We don’t mass-produce at all. Each and every component is manufactured individually for that customer, according to their specifications. That’s why flexibility is particularly important in our manufacturing operations.”

UNIPORT6000 pendulum machine

“How can we achieve an almost 100% spindle run-time?” That was a major consideration when purchasing the UNIPORT6000 pendulum machine in 2019. Willi Maier explains, “Whenever we’re clamping or retooling, that means downtime. So, we thought about having an external set-up station. But to process parts up to 12.5 metres in length, you need at least 12.5 metres of space around the machine. Our question to Unisign was: how long can a UNIPORT6000 machine be. The answer: 28 metres. We can now process our large components with pendulum machining on this machine.”

On the second UNIPORT6000 machine delivered to HOMAG in 2019, the clamping table is ‘only’ 14 metres long. This second machine has the same design as the first , but is used as a stand-alone machine. Willi Maier elaborates, “We purchased this machine mainly to produce our entire range of special parts. We work with a lot of complex welded constructions, and we can process them with extreme precision on this machine.”

Less downtime during set-up

Before the 28-metre-long UNIPORT6000 was installed in the same place, HOMAG was already using another UNIPORT6000. That meant that the same machine base could be used. Maier says, “We left the old machine in place while the first half of the new machine was being built. Thanks to Unisign’s excellent project management, we were able to extend the machine base and carry on working on the old machine at the same time. That helped us a great deal, as it kept downtime to an absolute minimum.”

A new lease of life

One other thing that speaks volumes about Unisign is the fact that the old machines were dismantled and re-purposed rather than scrapped. Willi Maier explains, “We sold our former Uniport 7 machine to Poland. And both of our old UNIPORT6000 machines went to our sister companies in Brazil and Shanghai. So, they certainly haven’t run their course at HOMAG; in fact, they’ve been given a new lease of life!”

In focus

Uniport6000

Specification

- X-axis4.000-24.000+ mm

- Y-axis1.500-5.000 mm

- Z-axis1.000 / 1.250 mm