UNIPORT6000: The beating heart of the production process

November 26, 2020

UNIPORT6 becomes UNIPORT6000 – discover our case study of Homag Kantentechnik GmbH.

HOMAG Kantentechnik specialises in producing edge banding machines, particularly for the furniture industry, with over 60 years of experience in the sector. “We supply our machines to a wide range of customers all over the world,” explains Factory Manager, Ernst Voß, “specifically in the handcrafting and small industry market segments. If you went and bought a cupboard from the carpenter around the corner, then there’s a very good chance that the individual parts of that piece of furniture have been processed by a machine that was produced by us.”

Unisign is no stranger to the HOMAG Group. Production Manager Manfred Kintzen says, “We have several production sites with machining facilities here in Germany, where we use Unisign machines to process large components for the machines that we produce ourselves.”

UNIPORT6

In 1999, HOMAG Kantentechnik GmbH – formerly known as Brandt Kantentechnik GmbH – purchased a UNIPORT6, a portal machine that was installed the following year.

“It was the machine’s reliability and flexibility that really won us over,” continues Manfred.

“We were able to configure the machine in a way that needed relatively little set-up time, meaning that we could change everything over quickly – in just a few minutes.”

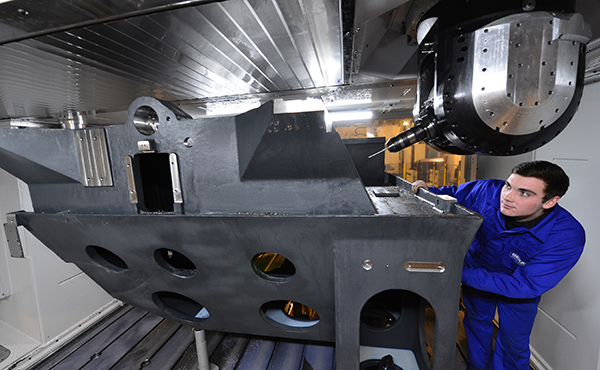

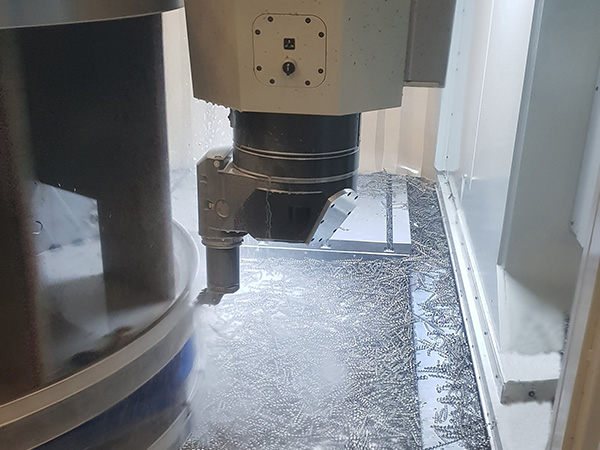

Machining base frames

HOMAG Kantentechnik GmbH uses portal machines from Unisign to machine bases for its edge banding machines. Ernst Voß says, “We produce a range of machines that have a long, narrow base construction, and our Unisign machine is used to process the base frame. The base frames are welded constructions measuring up to 10 metres long, approx. 1 metre wide and around 1.4 metres high. And we always produce them individually, never in series. So, our needs are rather broad, and Unisign offers the versatility that we need.”

6 becomes 6000

The UNIPORT6 has served HOMAG faithfully for 20 years, and it’s not going anywhere yet as Manfred explains: “Unisign updated our UNIPORT6 with the latest technology, converting it into a state-of-the-art UNPORT6000. The existing machine bed was still in good condition, so we kept it. It was only the portal bridge and controls that needed to be replaced.”

Playing a key role in production

Manfred continues, “Without our Unisign machine in operation, our production would grind to a halt. So, it’s quite simply a machine we couldn’t do without. When it comes to our production processes, the devil is in the detail, and flexibility is everything. As a process step before the UNIPORT we do welding work on one day. The next day we carry out machining work on the UNIPORT. Then the following day, the machine that we are manufacturing goes into assembly. The components that we machine using the UNIPORT6000 are used during assembly. So, if we cannot machine them, then they cannot be assembled. The Unisign machine is essentially the beating heart of our company. A high level of reliability is absolutely essential for us.”

Conversion process

Converting the UNIPORT6 to a UNIPORT6000 has had a huge effect on production at HOMAG Kantentechnik. How exactly? Ernst Voß tells us. “The process took around five weeks, all in all. We tried to prepare as much as we could beforehand, so we could minimise the impact on production.

We also had close discussions with Unisign in the run-up and throughout the process. It was quite a challenge for us.”

Manfred Kintzen adds, “We are incredibly satisfied with the work performed by Unisign’s teams and are proud of our own staff as well. They’ve done an outstanding job.”

Ernst concludes: “We’ve developed an excellent relationship and partnership with Unisign. We are very satisfied with how the work was planned and carried out, and we knew we could always count on a high level of service and support from them.”

In focus

Uniport6000

Specification

- X-axis4.000-24.000+ mm

- Y-axis1.500-5.000 mm

- Z-axis1.000 / 1.250 mm