The perfect fit for bogie machining

April 29, 2024

Medha Servo Drives is an organization with a 40-year history, primarily serving the Indian Railways. Their product portfolio for the railways includes propulsion, signaling, traction equipment, and fully assembled bogies.

Meeting the growing demand for trains

Recognizing the increasing need for semi-high-speed trains in India, Medha ventured into the design and manufacturing of bogies. To meet this demand, Medha Bogies Pvt.Ltd. was established, specializing in manufacturing newly designed bogies for the prestigious Vande Bharat Express trains.

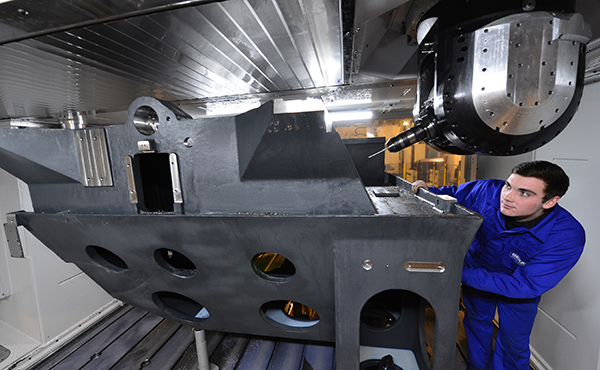

Why the UNIPORT6000?

Anil, Asst. General Manager at Medha, explains: “Unisign was renowned for its CNC machines in the railway and wind power sectors. After initial discussions, it became evident that their UNIPORT6000 was an ideal solution for machining bogie frames. Renowed companies in the railway industry in Europe were already using several Unisign CNC machines. Our primary reason for selecting Unisign was the quick cycle times of the UNIPORT6000 and the expertise of their team in machining bogie frames.”

Enhancing productivity and flexibility

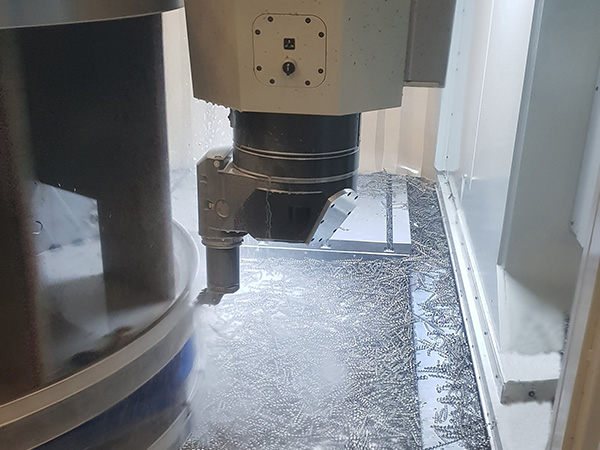

Two essentials stand out for manufacturers of train and tram bogies: productivity and flexibility. The UNIPORT6000 offers a reliable machining center combining high capacity and capability with high dynamics, rapid acceleration, and quick tool changing times. In addition to its time-saving productivity, it boasts exceptional versatility and impressive dimensions.

Efficient installation and low cycle times

“The installation and commissioning process went smoothly. It was a pleasure working with the skilled and experienced assembly and installation engineers from Unisign. Even though the team was

given the task of machining the bogie frames in a stipulated time, the engineers focused first on optimising the machining process. This resulted in a streamlined process that ensured minimal loads on the machine spindle while achieving the promised low cycle times.”

Testimony to performance

The Asst. General Manager from Medha reflects, “It has been eighteen months since we commenced using the Unisign machine, and we are pleased with its performance.”

In focus

Uniport6000

Specification

- X-axis4.000-24.000+ mm

- Y-axis1.500-5.000 mm

- Z-axis1.000 / 1.250 mm