Increased production for PALMS forest trailers

January 25, 2022

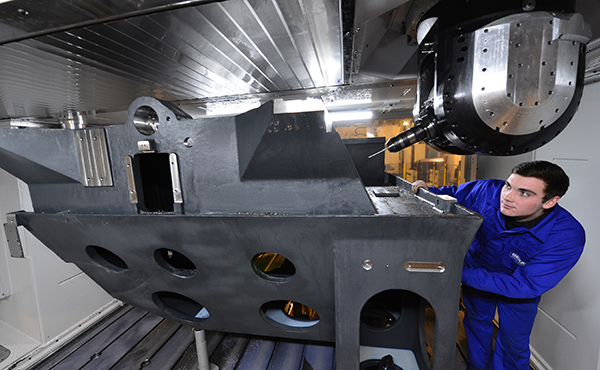

Due to growing demand for forest trailers, Palmse Mehaanikakoda needed to increase their machining capacity. So, in 2019, the company ordered a new machining centre: a UNIPORT6000. This portal CNC machine enables them to produce the steel vehicle frames much faster and at lower cost per piece.

Palmse Mehaanikakoda LLC is a mechanical engineering company, located close to Palmse in Estonia. Founded more than 20 years ago, the company produces forest trailers and cranes, designed for use with agricultural tractors. Palmse Mehaanikakoda is market leader in Europe and Scandinavia. Its continuous innovation and product improvement are the key to its success in the European forest and agricultural machinery market.

Gantry type: smallest footprint

The UNIPORT6000 is supplied in a gantry configuration with travelling bridge and stationary table. The moving gantry is a good choice from a cost perspective as it takes up the least space in the production facility.

Economic and flexible solution

The advanced UNIPORT6000 is fast, versatile, precise and easy to access. Operators can easily step onto the table to change clamps and workpieces.

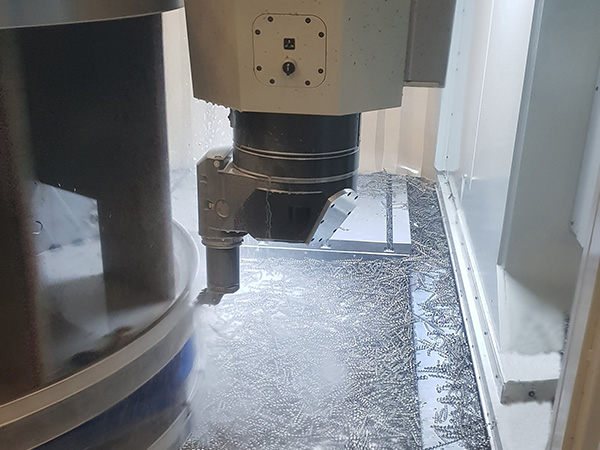

The work area is flexible too. The entire lenght of 10 m can be used for one large piece. Or as needed Palmse Mehaanikakoda can create two smaller stations which are separated by a screen for pendulum machining. The pendulum configuration offers a dedicated and economical solution for their growth plans. In the pendulum configuration, the spindle is put to maximum use.

Powerful geared spindle

The UNIPORT6000 incorporates a powerful gearbox driven spindle for high performance. With the standard spindle head and optional Unisign right angle head, it is the ideal production machine for large, multi-sided components. In future the machine can be expanded with additional heads. The various machining heads are stored in a pick-up station in one of the columns. Tools are exchanged automatically, always ensuring the shortest tool change times.

Palmse Mehaanikakoda choice for Unisign

Besides the flexibility and technical benefits for Palmse Mehaanikakoda, after seeing a similar UNIPORT6000 in operation and hearing how extremely satisfied and positive the Estonian users are, Palmse’s choice was made: firmly in favour of the Unisign CNC machine.

Service and support

In Estonia Unisign provides excellent local service and backup through partner Nordcity Center OÜ.

>> Download the full case study

In focus

Uniport6000

Specification

- X-axis4.000-24.000+ mm

- Y-axis1.500-5.000 mm

- Z-axis1.000 / 1.250 mm