Increasing manufacturing speed with Unisign portal machining centres

June 3, 2021

STT Servis in Dlouhá Loučka (Czech Republic) is a family company founded in 2001. In its early years, the company mainly focused on manufacturing medium-sized adapters for loaders, galvanised steel pallets for cylinder sets containing technical gases and producing weldments based on technical drawings. Since 2008, the core business has consisted of producing custom-made weldments and machining sheet metal. Regular orders are important to the firm. These come mainly from global automotive industry suppliers as well as companies in the food and food processing industries.

High-end CNC machines are crucial to the precision work that STT Servis delivers. For this, STT Servis has an extensive range of machinery at its disposal, which it deploys to meet the requirements of its demanding clients. “We provide a comprehensive service including all the necessary steps to complete an order,” explains Managing Director Tomáš Ticháček. “We prepare the custom drawings, source the raw materials and program the CNC machine to perform the burnishing, welding and machining.”

Unique machining concept

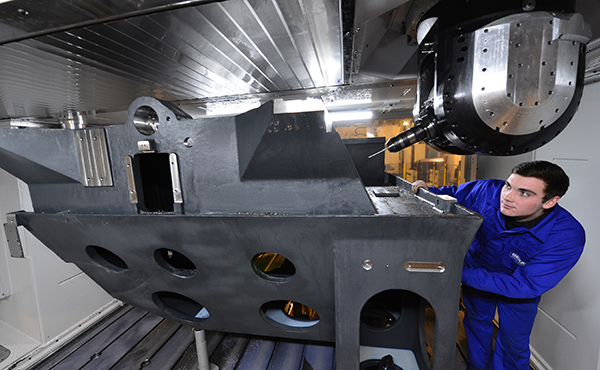

In 2017, STT Servis bought its first UNIPORT4000 machining centre. Tomáš Ticháček: “We know Unisign through MRM Machinery, our supplier of machining tools, which also represents Unisign in the Czech Republic. What appealed to us most was the concept of the UNIPORT4000 machine with a travelling bridge and stationary table. We have many CNC machines, but this was something completely new for us. The configuration simplifies the process of handling and machining weldments and sheet metal considerably.”

Flexibility in production

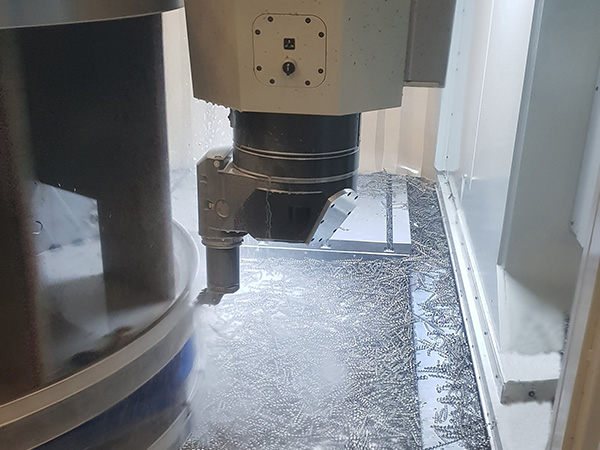

In addition to the UNIPORT4000, SST Servis has a second Unisign machine, a UNIPORT6000. The UNIPORT4000 is mostly used for drilling, tapping and milling sheet metal and flat weldments. The UNIPORT6000, with its angled head, is used for multi-sided machining of larger weldments. Tomáš Ticháček: “We process individual products as well as products in series, mainly steel. This combination means our machining process needs to be very flexible. The Unisign machines meet this need.”

Need for speed

“The speed and accuracy of the Unisign machining centres is really good,” Tomáš Ticháček continues. “For example: on the UNIPORT4000 we do the same amount of work as we did before on two or three traditional CNC machines.

“In the past, it used to take us four hours to process some parts, now we can do the job in just one hour. It’s a reliable machine which helps us save time and money. What’s more, our people can work much more efficiently.”

“Clients are continually requesting more from us. Three years ago, lead times of five or six weeks were normal, now they expect delivery within two or three weeks. To cope with the increasing pressure on lead times, we have decided to purchase a second UNIPORT6000, further increasing our capacity and decreasing our delivery times.”

Installation and service

SST Servis is very satisfied with the technical installation support and service provided by Unisign. Tomáš Ticháček: “Unisign’s support during installation was very professional. We work with CNC machines from various suppliers, but never before had we experienced this high level of service. And the same applies to their after-sales service. If anything goes wrong, Unisign responds quickly and also provides good technical support over the phone.”

Tomáš Ticháček concludes: “Our overall experience with Unisign is very positive. We are very satisfied with the two Unisign machines we already had, and that is the main reason why we ordered a third. We really need these CNC machines. The Unisign machines are helping us meet our clients’ requirements better and faster.”

In focus

Uniport4000

Specification

- X-axis4.000-24.000+ mm

- Y-axis1.500-3.500 mm

- Z-axis500 / 600 / 750 mm