Performing multiple operations on complex welded structures

September 29, 2020

We are very proud to share a case study of our highly valued customer VDL Konings, the Netherlands.

Konings was founded in Swalmen in the Dutch province of Limburg, all the way back in 1873. The family-run business started out as a machine factory, adding an iron foundry in 1898. Over its rich history of more than 140 years, Konings has built up an impressive list of achievements, even building the first cars in the Netherlands in 1898 and a twin-engined truck in 1936.

Over the years, Konings has become a key player producing high-quality machines for agriculture, chemicals, and the textile, foil, foam and paper industry. Since 2005, the company has been part of the VDL Groep and its registered company name is now VDL Konings. Around 100 people work at its production site in Swalmen.

VDL Konings specialises in developing, building and installing machines, as well as supplying mechanical components and modules for various industries including defence, automotive and medical. This is ypically done as turnkey projects. VDL Konings then takes care of the entire engineering process, up to and including installation, with quality being the core focus throughout every phase.

Mechanical components for medical devices

VDL Konings was approached by a medical device manufacturer, asking the firm to produce a number of mechanical components. Sales Manager Erik Leppers says, “They wanted to move their production from China to Europe, so we had to come up with a smart way to structure their production. For this smart solution, we needed special equipment, such as a multifunctional CNC machine, which became the UNIPORT6000.”

More machining, less time wasted

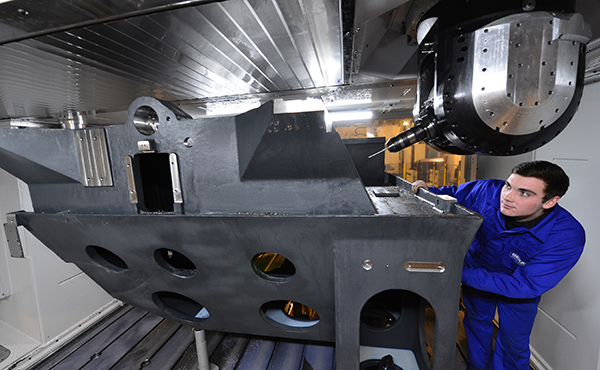

VDL Konings produces the assemblies in multiple parts that are subsequently welded together by robots. Erik continues, “We carry out various operations on these complex welding structures, and wanted to machine the assemblies simultaneously. The UNIPORT6000 offered us that possibility. Our UNIPORT is equipped with pendulums to reduce downtime to a minimum. We also opted for a carrousel station especially because of the turning operations we were asked to do.”

Not just a standard machine

“Unisign was right to approach this as a turnkey project,” says programmer Roel van der Varst, “which is exactly what we do for our customers. On top of providing extensive technological advice, they also supply all the clamps and tools you need. Many other suppliers just provide you a standard machine with zero flexibility. Unisign builds a single, tailor-made machine that you can perform all of your operations on. That’s what they do best.”

Experience with Unisign

Roel is satisfied with the progress of the process, even more so with how the UNIPORT6000 performs. He continues, “Together with Unisign’s engineers, we tailored the machine to our own preferences. My experience with the UNIPORT6000 has been very good. The machine is stable, has a high uptime and processes components quickly and accurately. It can turn, mill and drill components that are long and big or big and flat perfectly, no matter what type of steel it is.”

Erik concludes, “Until the new machine could be delivered, Unisign processed parts for our customer at its own site. That meant we could start the validation with our customer in the preliminary phase. That extra service from Unisign was invaluable to us.”

In focus

Uniport6000

Specification

- X-axis4.000-24.000+ mm

- Y-axis1.500-5.000 mm

- Z-axis1.000 / 1.250 mm