UNICOM6000 – indispensable for production of large pumps

February 25, 2021

Discover our new case study on the Wilo Gruppe: one of the world’s leading manufacturers of high-tech pumps and pump systems for use in building services engineering, water management and industry.

“Our activities in this segment first began with the production of heating pumps, and that still forms a major branch of our company’s operations today” says Stefan Mohr, Head of Technology & Service at the company’s site in Hof. “Here in Hof, we also manufacture large wastewater and drinking water pumps. These pumps are used in municipal and industrial water supply systems, as well as for the removal and treatment of wastewater. We supply our products to end-users, but also to well-known original equipment manufacturers the world over.”

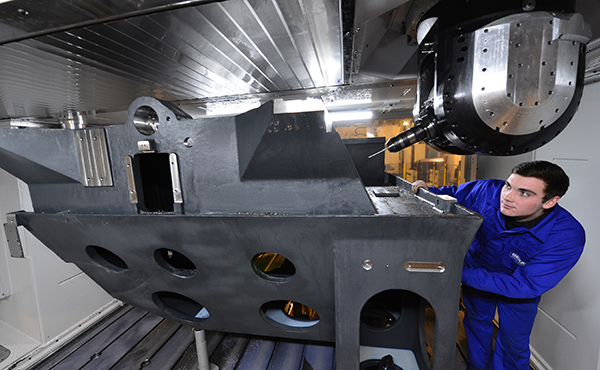

In 2009, Wilo purchased a UNICOM6000 machine from Unisign. Stefan Mohr continues: “We had heard lots of good reports about the accuracy of the machine, and that was an important factor for us. And now, after 10 years of use, it still is a very reliable machine. We use it daily at our site in Hof to machine pump housings.”

Large industrial pumps

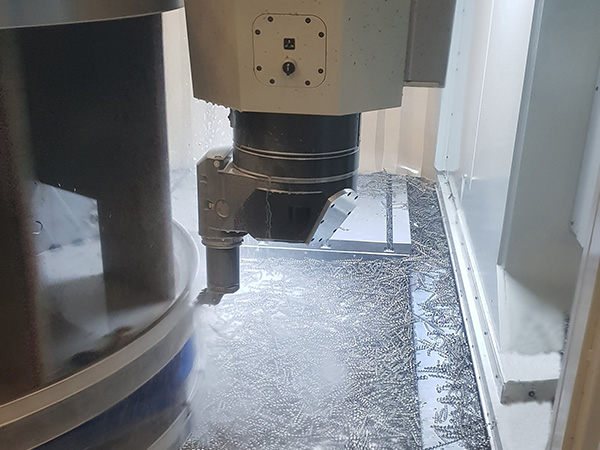

As mentioned before, the UNICOM6000 is used to machine pump housings for large industrial pumps, such as wastewater pumps for sewage treatment plants. As Stefan Mohr also points out: “The largest pumps we produce have a diameter of around 1.3 metres and are over 2000 mm high. The components that we drill, turn and mill using our UNICOM6000 always consist of 1 to 3 individual pieces per set, in a variety of sizes. In most cases, they are made of cast iron.”

Multi-tasking

The UNICOM6000 is what is known as a multi-task CNC machining centre for milling, drilling and vertical turning operations. For Wilo, it was the perfect choice.

“For us, it’s important that we can fully machine the components of our large pumps, from start to finish. What is more, the high degree of accuracy we require must be maintained at all times, and this machine meets our requirements.”

High availability

Another one of Wilo’s requirements was the ability to load a new component onto the machine “while the machining of the other component is still in progress”. As Stefan Mohr explains: “The automatic pallet changer, which is supplied with the UNICOM6000 as standard, makes that possible. This allows us to make the most efficient use of the machine. One of the other strengths of this machine is its magazine with multiple machining heads. In addition to that, the machine is extremely accessible.”

A reliable member of our team

At Wilo, reliability is the highest priority, as its customers place a great deal of trust in the high-quality pumps that the company supplies. This means that Wilo also needs to be able to rely on the machines that form part of the production process. As Stefan Mohr explains: “The reliability of the Unisign machine is very important to us. After all, the UNICOM6000 plays a key role in our production process. It mustn’t malfunction, as we wouldn’t have any other way of producing our pumps. We also have only limited alternatives available, so the machine needs to be reliable, and it certainly is that!”

“Apart from replacing the usual wearing parts, we haven’t suffered any malfunctions at all in 10 years of service”, says Stefan Mohr, “even though the machine is in continuous use as part of our dual-shift operation. It rarely needs any attention from Unisign’s maintenance technicians! But when it does, the level of service is excellent. Here at Wilo, we’re very satisfied with the customer service. Unisign is a competent partner that provides good support in all areas.”

In focus

Unicom6000

Specification

- X-axis1.950 mm

- Y-axis1.425 mm

- Z-axis1.000 / 1.250 mm