Retrofitting controls extends lifespan of legacy machines

July 7, 2022

Coek Engineering in Belgium has two UNIPORT7 CNC machines in its workshop. The first gantry machine was installed in 2000 and a second gantry machine followed three years later. The newer machine also has a carousel turning station. These machines have been working to everyone’s satisfaction for more than 20 years.

After two decades, it had become difficult to obtain replacement parts for the old NCU. This posed a continuity risk for the company’s operations. Coek was looking at the options to guarantee continuity of production. The current machines are not up for replacement and they still perfectly meet the present requirements. So, a retrofit was the next logical step to consider.

In close consultation with Coek, Unisign prepared a plan to retrofit the machines. This upgrade offers Coek many advantages.

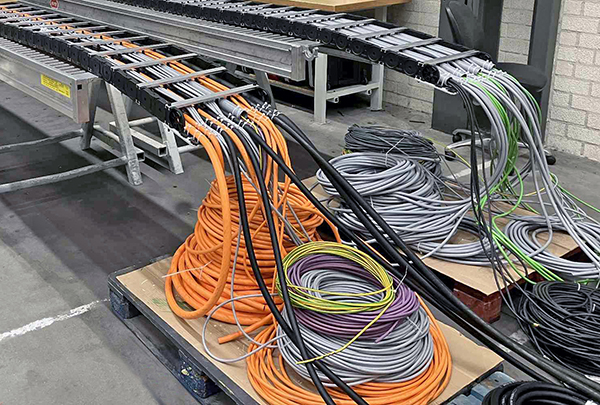

Entire NCU replaced

The first machine was retrofitted in 2019 which involved replacing the entire control system:

- A new control panel with all new electronic components.

- A new PC with USB and network connections, offering Coek much greater flexibility.

- A complete software upgrade which enabled new functionality to be added to the machines, including remote fault diagnosis.

- The NCU, the heart of the machine, was replaced with a much more powerful version which is also compatible with the newest software settings for the ‘840D pl’.

- A software upgrade for the NCU as well as the PLC. This upgraded the tool change functionality to the newest level.

- The Artis tool monitoring system was also upgraded. This functionality is indispensable for Coek, considering the critical machining with very long tools they perform when drilling deep holes. This software automatically monitors the tools for damage during machining.

Satisfied with planning and implementation

Unisign had planned to complete retrofitting the first of the two UNIPORT7 CNC machines within two weeks, so Coek was very happy when the work was completed within a week and a half. In 2020, Unisign service engineers upgraded Coek’s second machine.

Willy Claessen, Production Manager at Coek, looks back with satisfaction:

“We were very satisfied with the planning and the work conducted during these two retrofits. Since then we haven’t had any disruptions. We have been able to use both machines for machining parts which are essential to the process equipment we manufacture.”

Old machines now as good as new

Retrofitting their existing CNC machines was an efficient and attractive solution for Coek Engineering. The machines are as good as new and future-proof. Coek has no more concerns about the availability of essential electronic components.

In focus

Uniport7000

Specification

- X-axis6.000 - 24.000+ mm

- Y-axis2.500 - 6.500 mm

- Z-axis1.600 mm