Unisign’s friendliness and willingness to help stand out

December 5, 2023

With pleasure we share a new case study on our customer KNDS UK.

KNDS UK specialises in the manufacture of tactical military bridges and represents the UK branch of the KNDS Group from its base in Stockport. The company has been a supplier to 43 armed forces around the world for over 50 years and is a global leader in rapidly deployable bridges, backed by over a century of technical expertise. The company is also a key partner to the UK MoD Boxer Armoured Vehicle programme.

KNDS UK uses two Uniport 7 machines, built by Unisign, to manufacture nearly all components for its bridges and vehicles. Their CNC machines have been at the heart of the manufacturing process for 20 years. “These machines are pivotal to our business”, comments John Mawdsley, Technical Support Manager at KNDS UK. “A lot of our key components go through them. ”

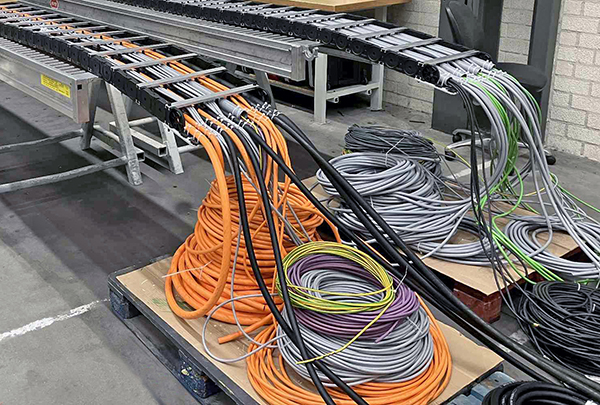

Considering the relatively high age of the machines KNDS UK asked Unisign for a refurbishment: to replace all main components of the Uniport 7 machines, one at a time. The first step consisted of a full rewire, which Unisign completed in the summer of 2023.

Tailor-made refurbishment plan

It is crucial to KNDS UK that any manufacturing interruptions are kept to an absolute minimum. As John explains: “Several years ago we looked at replacing our machines with the newer version, the Uniport 7000. Unfortunately, we discovered that would take too much time. We’d have to remove the old machines, put the new foundation in, and install the new ones.

We don’t have that sort of gap in our production schedule, so that’s why we decided to refurbish the current CNC machines. Together with Unisign, we created a complete package of components to replace or upgrade, without upsetting the production too much. We discussed this in-depth and came up with a plan with input from both sides.”

Finishing early

The cables on the Uniport 7 were one of the first focus areas. As time passed by, the cables lost some of their flexibility and became a more frequent source of faults, according to John. “They’re part of an energy chain and constantly bending and flexing. With time, the cables can become brittle and fail. So Unisign sent two of their engineers over to replace the cable package for us. The whole replacement took a little under three weeks. I spoke with the engineers daily, both very friendly guys. Everything went mostly according to plan and they even finished a couple of days earlier. We were able to pick up production quicker than expected.”

Sharp reduction in breakdowns

The rewire has made the CNC machines run much more smoothly again. Mawdsley: “They’re twenty years old, so they do break down occasionally. Since Unisign replaced the cables, the machines haven’t had any major issues, and there are fewer breakdowns. The next step in the refurbishment is replacing several mechanical components, which Unsign’s engineers will also take off our hands. These new components will give the CNC machines increased accuracy.”

High-quality machining heads on loan

In addition to this extensive refurbishment, KNDS UK also regularly sends over CNC machine components for upgrades and repairs. “There are certain parts that attach to the machine that wear down quickly, and so they need to be fixed regularly. When that happens, we send the whole unit to the Netherlands and Unisign repairs it for us. ”

Unisign carries out the repair inhouse, while providing KNDS UK with a machining head on loan, so manufacturing can continue uninterrupted. “They send us a high-quality machining head to use in the meantime. Quite a unique service among machine manufacturers.”

Always willing to help

On the rare occasion that an issue does arise, Unisign is at hand to assist John and his team over the phone or remotely. “If we can’t source an issue, maintenance will ring up Unisign and their engineers will guide us through diagnosing it. There’s never anything that they don’t know how to fix. Sometimes they’re unsure, but they’ll always get back to me with an answer. Unisign’s friendliness and willingness to help stand out.”

In focus

Uniport7000

Specification

- X-axis6.000 - 24.000+ mm

- Y-axis2.500 - 6.500 mm

- Z-axis1.600 mm