Completely care-free solution for machine relocation

February 6, 2023

CNC machines frequently need to be relocated for a wide range of reasons. If machine relocation is a challenge facing you in the near future, the Unisign team would be happy to assist and make the relocation hassle-free. To achieve this, we will work according to a detailed, well-designed plan.

Professional support for relocations

Moving a CNC machine is a technically demanding task. Whether the machine is being moved internally or externally, if it isn’t relocated and installed properly, this will have a negative impact on your operations, for example extra downtime and potential geometry issues. Our experienced service engineers can help to prevent all of this when a machine needs to be moved. We will arrange and manage every step along the way.

Detailed step-by-step plan

Thorough preparation and a well-designed step-by-step plan are key to machine relocation. Our expert approach will keep downtime to a minimum for your machine. You also have the option to include an overhaul of your machine as part of the step-by-step plan.

1. Machine status report

Our first step is to carry out a detailed inspection of your CNC machine. You will get a clear picture of the condition of your machine (wear and tear on parts) and its geometry. The geometry report provides crucial information. It will indicate what geometry corrections, if any, need to be carried out during set-up.

2. Overhaul as needed

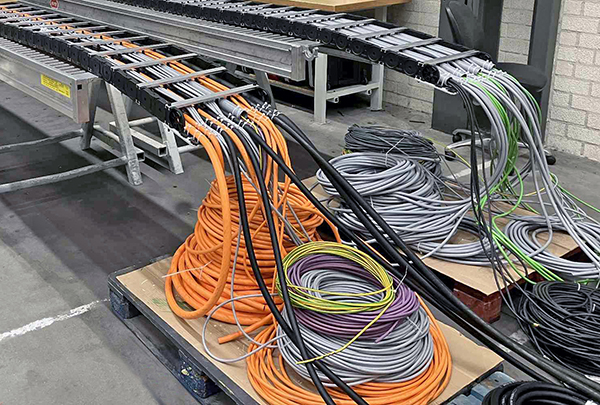

If you wish, we will prepare a proposal to replace worn parts. We can also include any repairs as part of the relocation process to ensure these do not result in any additional downtime. For older CNC machines, we can for example upgrade the operating system or completely rewire the machine.

3. Foundation at the new site

Before your machine is disassembled, we will provide you with extensive information on the correct installation requirements. You will receive foundation drawings that will enable you to adequately prepare the foundation of the new location.

4. Machine disassembly

Your CNC machine will be disassembled either by our own service engineers or by your own staff under the supervision of a Unisign specialist. Failure to disassemble a machine correctly can result in significant damage.

If the machine to be moved is a multi-task machining centre, additional care and attention is needed. These are complex machines that are made up of multiple components. The individual components must be geometrically re-aligned to ensure the re-assembled machine meets the applicable specifications.

5. Packaging and transport

We will provide appropriate and corrosion-resistant packaging to prevent any damage during transport. For the transport itself, we will engage a specialist carrier who uses appropriate and certified lifting and transport equipment.

6. Assembly

Expertise and accuracy are vitally important when it comes to assembling your CNC machine at its new location. Our skilled experts ensure set-up is completed within the shortest time possible. They will fine-tune the machine, test all its functions, and also analyse and resolve any faults.

7. Commissioning

The last step of our process consists of geometrical checks. These must confirm that your CNC machine meets the specified tolerances once more.

Ready for production

Your Unisign machine is ready to resume production. You now have a machine in good working condition, delivering accurate, high-quality products in its new location.

Relocation of UNICOM6000 machines

In 2022 we relocated two UNICOM6000 machines for Voith Paper GmbH, based in Heidenheim, Germany. After disassembly, the oldest machine (17 years old) was transported to Belgium. The second UNICOM6000 machine (dating from 2008) was moved to a client in Austria and re-commissioned at their site to their complete satisfaction.