Maintenance and after-sales supported by extensive knowledge

July 18, 2023

“Unisign’s people are highly experienced and highly qualified. This offers us much-needed peace of mind. After all, quick support is essential when something has gone wrong. “

Mogema is a high-tech expert in machining, welding, assembly and vacuum technology. Mogema became part of Aalbers in 2001 and manufactures ultra-large and accurate machine frames, vacuum chambers and mechatronic systems. The company serves the semiconductor, medical & analytical, oil & gas and defence industries, as well as the scientific community.

In order to machine products such as its machine frames, Mogema uses a large machine pool which comprises a number of large CNC machines. Among these is a UNIPORT7000-OG-KW. Responsibility for maintaining all the machines rests with Maintenance Engineer Arjen Schoonhoven and two Maintenance Technicians, who work in collaboration with a number of external contractors. For the UNIPORT7000-OG-KW, they receive support from Unisign. Arjen: ‘We entered into a three-year maintenance contract with Unisign. The machine receives one major and one minor service at regular intervals throughout each of the contract years. Unisign takes care of it all down to the smallest detail.’

100 hours of machining time

The UNIPORT7000-OG-KW is crucial to the machining of machine frames. ‘There are a number of operations we can only carry out using this machine,’ says Arjen. ‘Our machine frames are manufactured in series as part of a continuous process. We use a four-shift rotation and the machine runs 24 hours for 6 or 7 days a week. A single frame takes more than 100 hours to machine. There are a great number of steps involved and a very high degree of accuracy is required. So you see, we can’t really afford any downtime on this machine. Although we can’t avoid this completely, we do everything we can to minimise this.’

Clarity

Arjen concluded the maintenance agreement with Unisign when he came to work at Mogema some four years ago. Arjen: ‘The great thing about contracts like these is knowing precisely what maintenance will be carried out and when. The dates for the different types of services are planned well ahead of time. The Unisign service engineer arrives on site, does the work and leaves again. It’s all really well organised. Another advantage is that these contracts include a discount on all spare parts needed for the machine.’

Extensive knowledge

Troubleshooting for faults that occur in the interim are of course not covered by the maintenance contract. ‘But Unisign offers a quick response even in these cases,’ confirms Arjen. ‘Unisign’s people are highly experienced and highly qualified. This offers us much-needed peace of mind. After all, quick support is essential when something has gone wrong. A Unisign employee will help us troubleshoot the fault remotely first. If we can’t resolve things that way, a service engineer will come out.’

After-sales

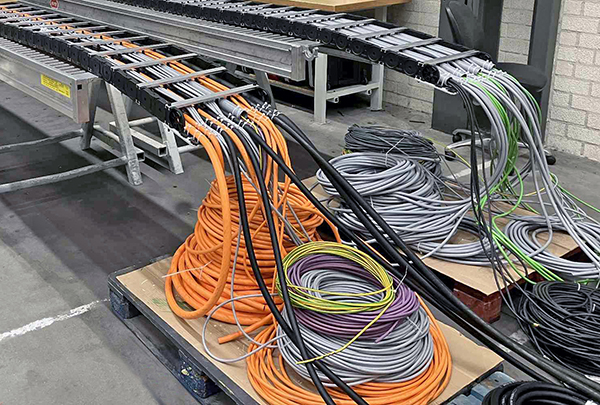

Arjen is equally happy with Unisign’s after-sales service, citing the following example: ‘Three years ago we ordered a fully automated brush unit for our 7000-OG-KW. We sent a request, received a comprehensive quotation and were happy to go ahead. The part soon arrived and the service engineer visited at the scheduled time. He had discussed every detail with the Unisign work planning department in advance and knew exactly what needed to be done. The brush unit was integrated into the paternoster tool store and adjusted. The new software was loaded and just like that, the machine was back in action once again. That’s how Unisign does things.’

The UNIPORT7000-OG-KW is now 10 years old and, as mentioned, is in use 24 hours a day for 6 or 7 days a week. Arjen: ‘Each of those years counts for two, probably more, in the machining industry. Certain parts wear more quickly on machines that operate continuously. Let’s take the special HV-machining head we use as an example. This component is crucial to our machining process. We can rely on Unisign whenever the machine has an issue. They usually have a rental head available for us.’

Total package

‘It would be great to have a few more Unisign machines,’ Arjen concludes. ‘It’s all about the total package that Unisign offer. The quality, reliability and accuracy of the machines is excellent and this is backed up by an equally brilliant organisation. At Mogema, we feel that is just as important. We have a solid, open relationship with Unisign.’

In focus

Experience

Specification

Uniport7000

Specification

- X-axis6.000 - 24.000+ mm

- Y-axis2.500 - 6.500 mm

- Z-axis1.600 mm