Preventive rewiring: Avoid wear and tear and increase reliability

October 24, 2023

A complete preventive rewiring of your CNC machine is advised every 12 years, based on a range of factors and industry considerations. Although this is not a hard and fast rule, there are several reasons why it is useful to do so.

Why a complete rewire?

These are five key reasons we recommend preventive rewiring:

- Wear and tear

The wiring in your CNC machine is subject to repeated movements, vibrations and aerosolised fluids, which cause wear, damage and even breakages to the cables over the course of time. This will affect the performance of your machine and could potentially result in unplanned downtime. - Technological obsolescence

12-year-old wiring may be obsolete compared with the latest technology. New wiring will offer better performance, such as improved signal quality and reliability, and can boost the overall efficiency of your CNC machine. - Safety

Safety is a key consideration in manufacturing environments. Older cables that have become damaged can present a greater risk of short circuits or fire. A rewire helps to minimise these risks. - Maintenance costs

Old cables can require more frequent maintenance and repair. The costs linked to this could exceed the cost of a preventive rewire over the long term. - Regulatory compliance

Some countries stipulate that cables and hydraulic hoses must be inspected and replaced periodically in order to comply with safety and quality standards.

How we work

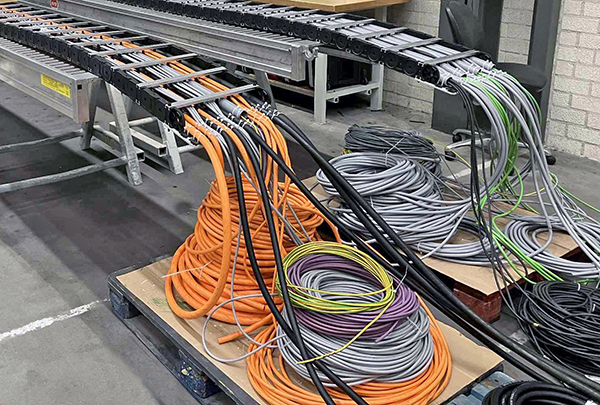

We will send you a quotation for a full rewire. Once you have placed your order, we will purchase all the cables, hoses and energy chains. Our experienced service engineers will pre-assemble the energy chain at Unisign, taking into account the length of the cable between the start of the chain and the control box or fixed end. Plugs and couplings at the control box end will also be pre-assembled. The cable assembly is then shipped.

At your site

There are just two things you’ll need to arrange before our service engineers carry out the work at your site:

- Ensure the machine is dry and free from machining chips

- Build a scaffold for safer access to the machine if needed

Our service engineers will take care of everything else. They will:

- Remove old cables, hoses and energy chains

- Install new energy chains in the machine

- Connect the cables to the control box

- Make all the connections at the machine end, and

- Test your machine upon completion to ensure it runs to your full satisfaction once again.

Why regular inspections are important

The exact time for a complete rewire will vary. This is influenced by multiple factors, including the conditions of use, maintenance history and technological developments. That is why we recommend regular inspections to determine whether a replacement is necessary, so the reliability and efficiency of your CNC machine is maintained.

If you are interested, please contact us at aftersales@unisign.com for advice without obligation.